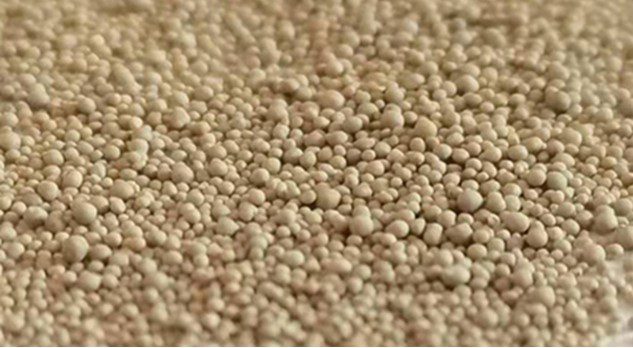

Sintered Ceramic Sand: HT2

Sintered Ceramic Sand (SCS) is a synthetic mullite sand for foundries, identical to Ceramic Foundry Sand. It suits all pour temperatures and binder systems, making it ideal for facing, cores, full molding systems, and additive manufacturing.

SCS enhances surface finish, reduces casting defects, and eliminates silica-related risks. Its high durability allows indefinite reuse, making it a cost-effective and sustainable alternative to traditional sand. It is also well-suited for 3D printing in foundry applications, offering high thermal stability, low thermal expansion, and precision for binder jetting and sand casting-based additive manufacturing.

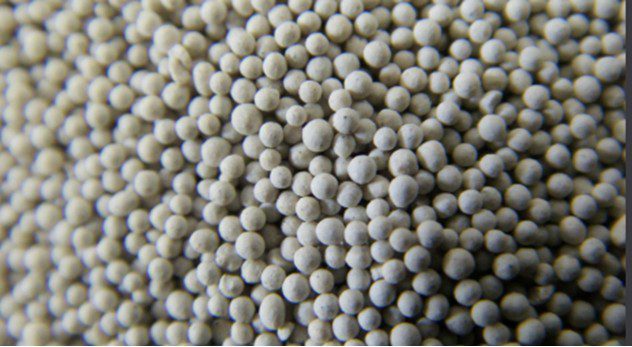

Next-Generation Sintered Ceramic Sand: HT-3

Our newest-generation Sintered Ceramic Sand (SCS) is a highly spherical synthetic mullite sand, offering even greater consistency and roundness than previous versions. Designed as a superior replacement for fused sand, it provides enhanced flowability, packing efficiency, and reduced binder demand—delivering exceptional mold and core precision in foundry applications.

SCS is engineered for all pour temperatures and binder systems, making it ideal for facing, cores, full molding systems, and additive manufacturing. Its high thermal stability, low expansion, and recyclability ensure cleaner castings, fewer defects, and long-term cost savings.

Additionally, SCS excels in 3D printing for foundries, offering unmatched uniformity for binder jetting and sand casting-based additive manufacturing, further reinforcing its role as the ultimate fused sand replacement.